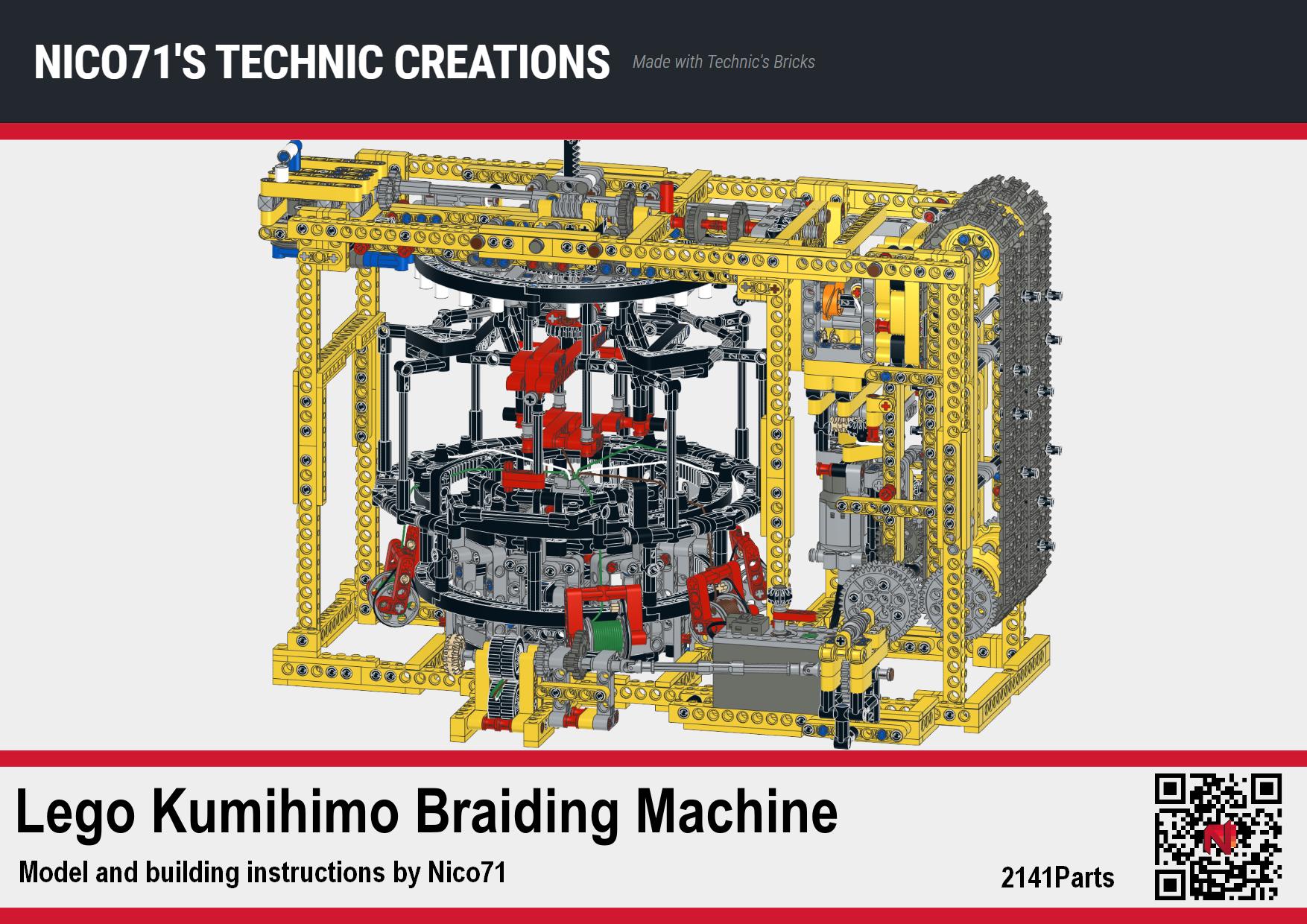

An automated Lego braiding machine, based on traditional Japanese 7 reels Kumihimo braiding to create a braid, with building instructions.

Direct purchase of the instructions

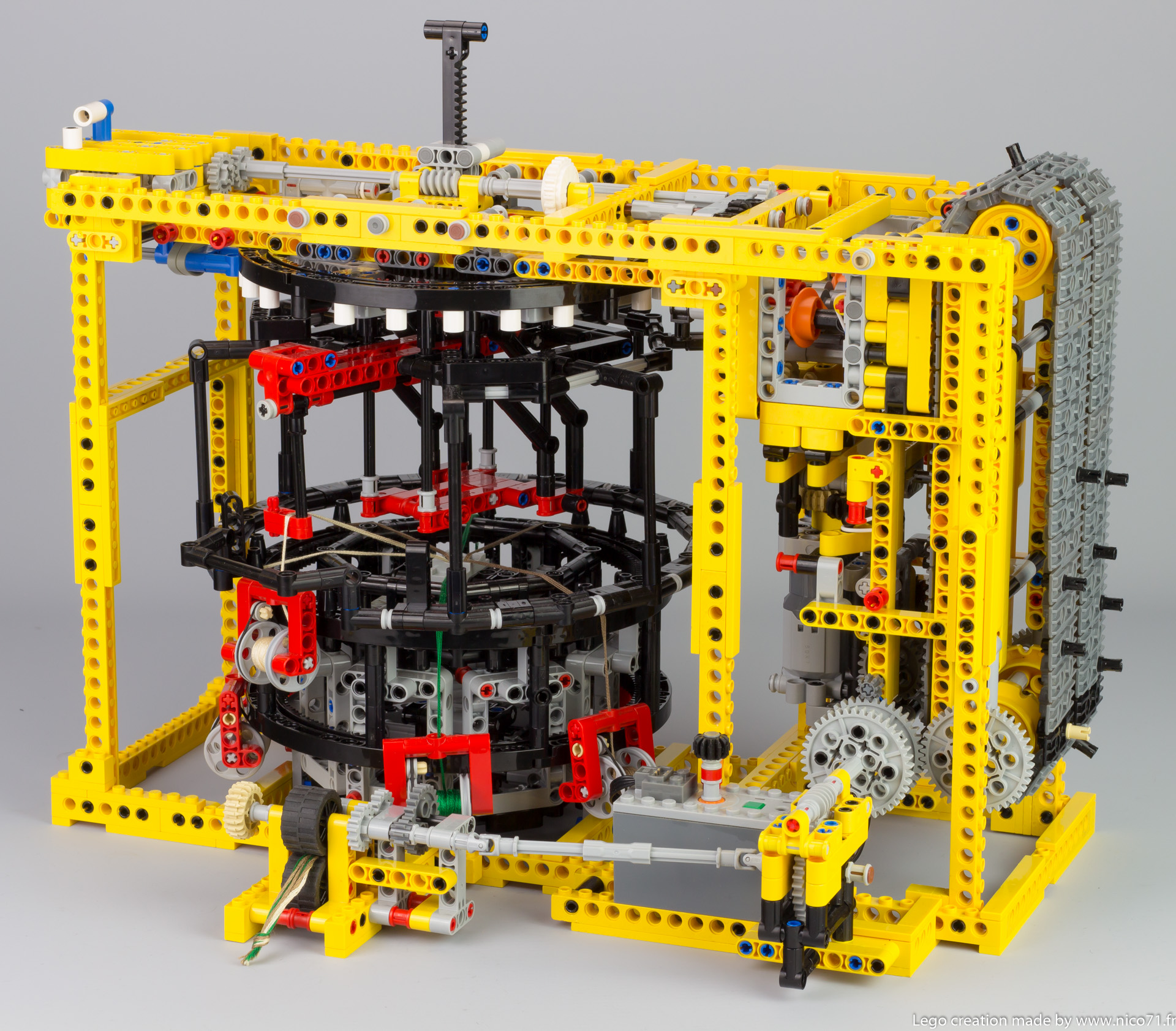

Kumihimo Braiding Machine

Preview of the instructions at the end of the article.

Context

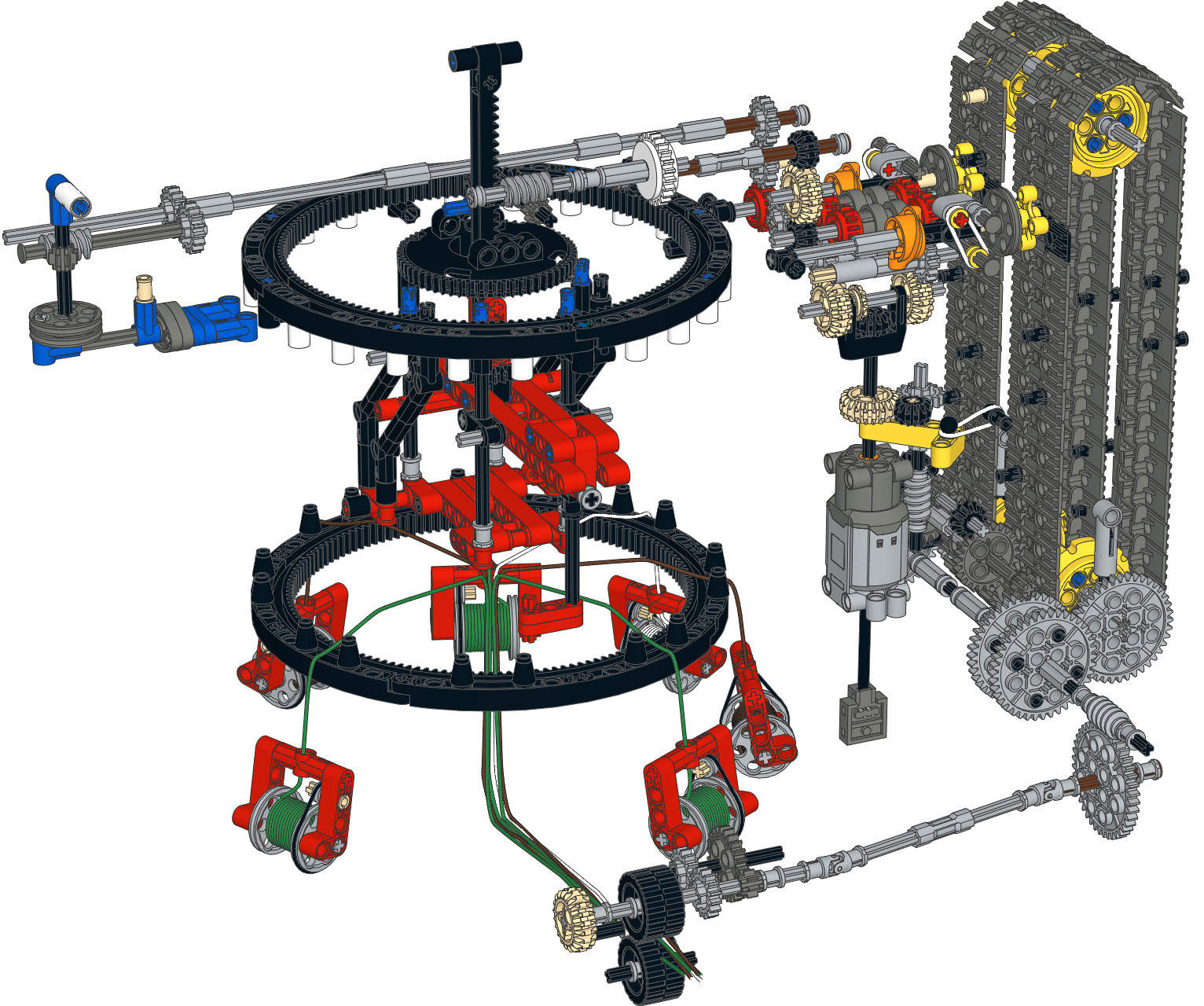

After discover the traditional Japanese Kumihimo braiding, I wanted to create an automated braiding machine to do it. The basic principle is that you have a disc with many reel holders, and by moving the reel, you create a braid. There are many possible variations about the number of reels and movements that you can do but I have chosen one of the simplest : 7 reels for 8 holder space. The idea is that you have always an empty space, and you move the third reel counter-clockwise to this position, then you rotate the disc to the new empty space and you repeat the sequence.

Functions

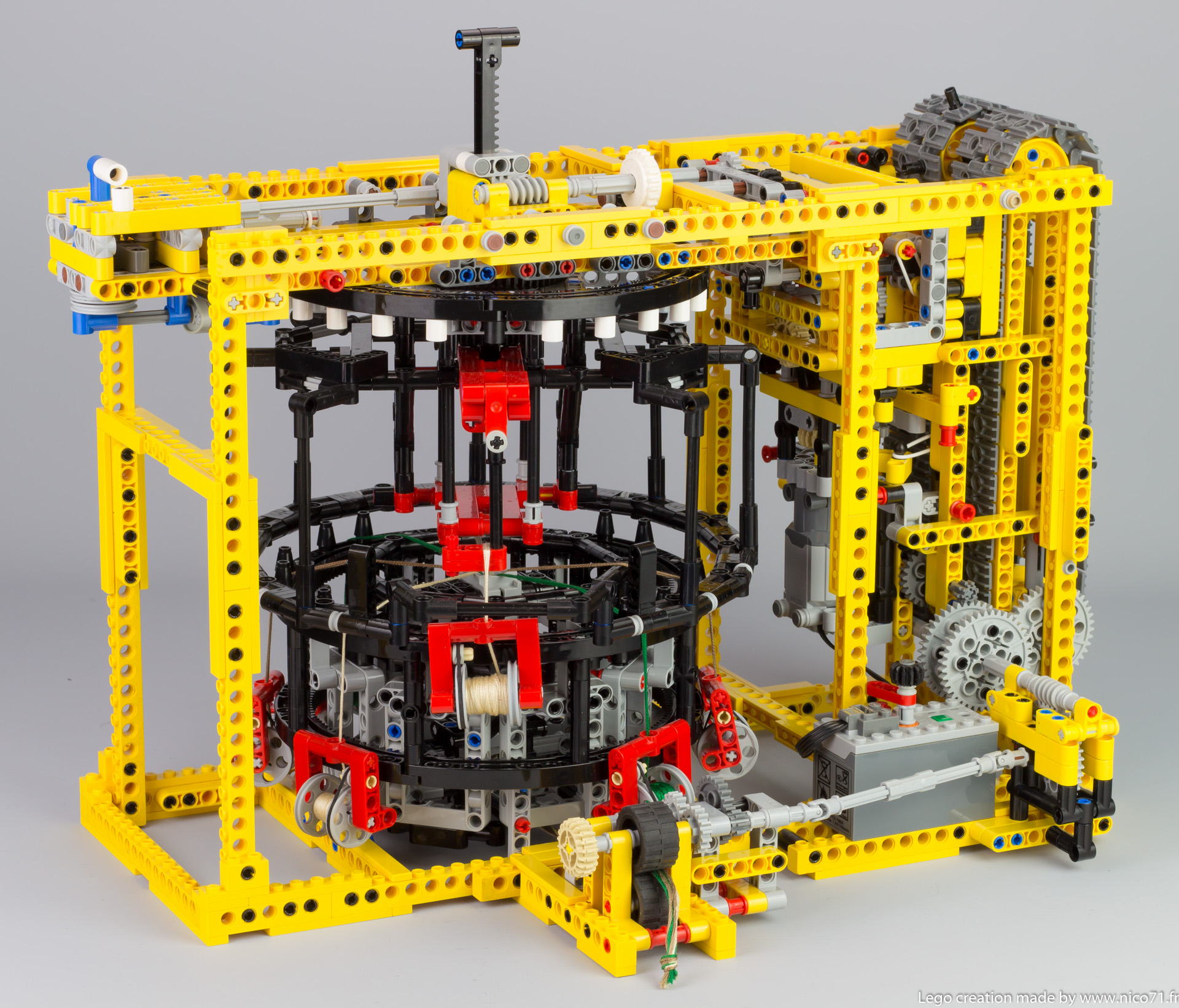

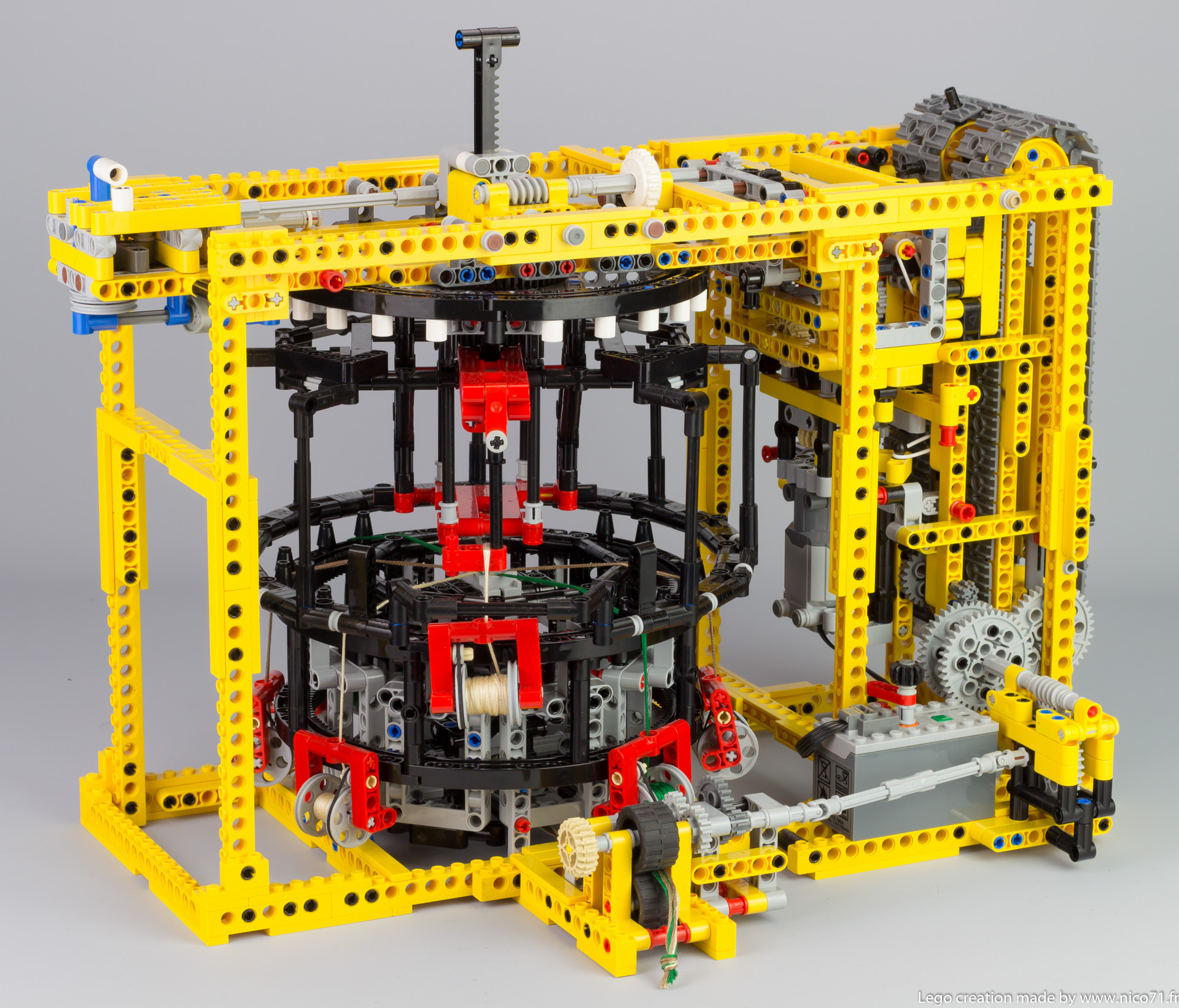

Instead of making rotate the whole disc, I have decided to have a fixed disc but with a rotating ring with the hook. The principle of having a hook to catch the reel has been inspired by this video which is an electronic programmed Kumihimo machine made with Meccano. I wanted to add some improvements, for instance, a main winder, a system to control the unwinding of the reel and of course make it mechanically programmed by creating a mechanical “brain”.

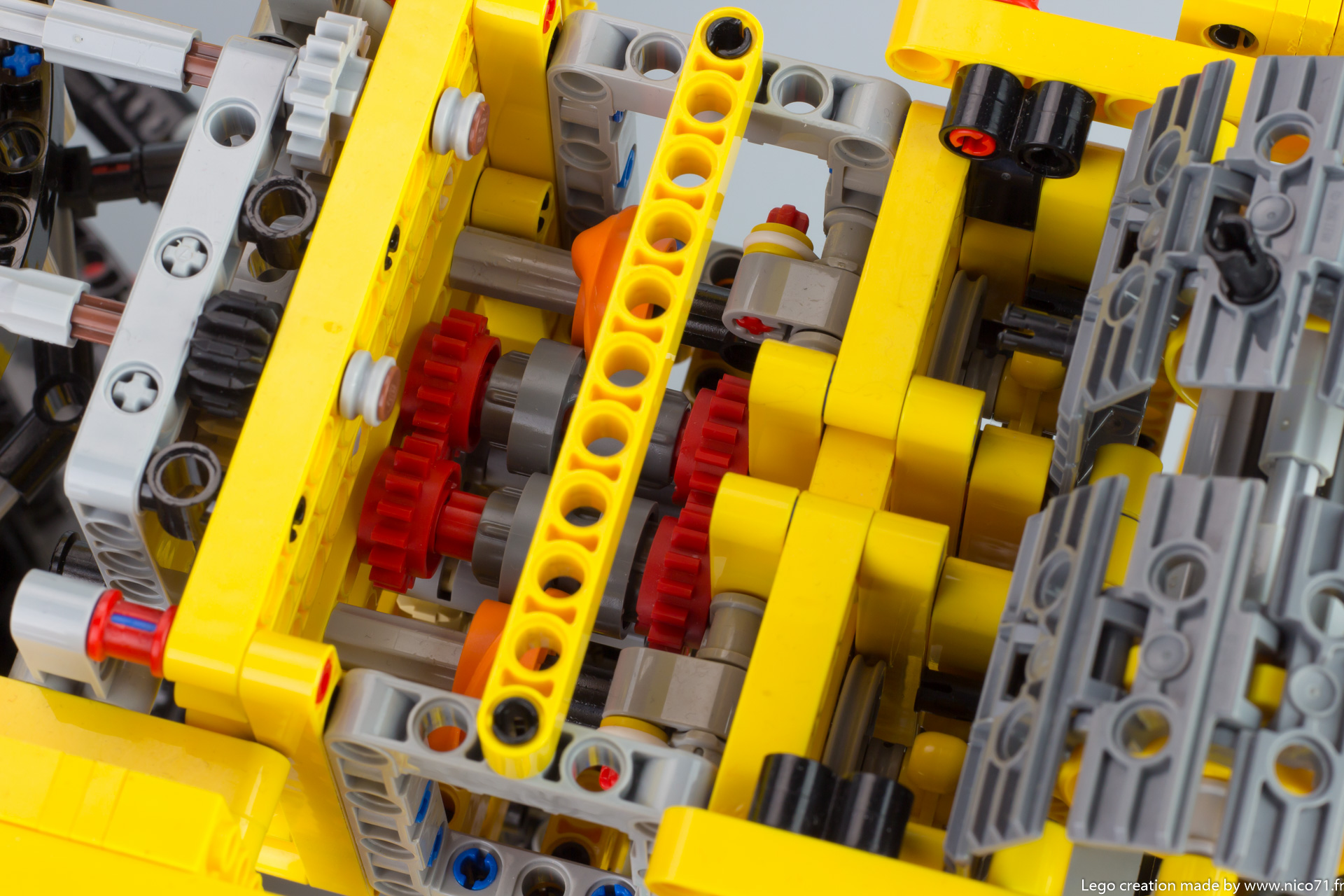

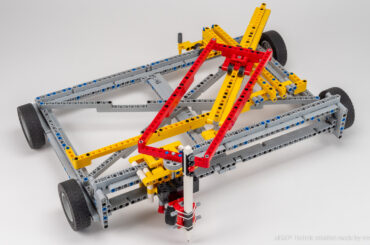

The “brain” of the machine is composed of two tracks with pins on it and output gearboxes powered by a L Motor. Each track operates a gearbox, and each pin on each track enables to control the way of rotation of the functions. This idea has been taken from my previous mechanical loom. I used the new gear shifter, combining with the knob wheel which enabled to create 1/4 turn to control easily the functions, in run / standby / back. You can see the whole mechanism below :

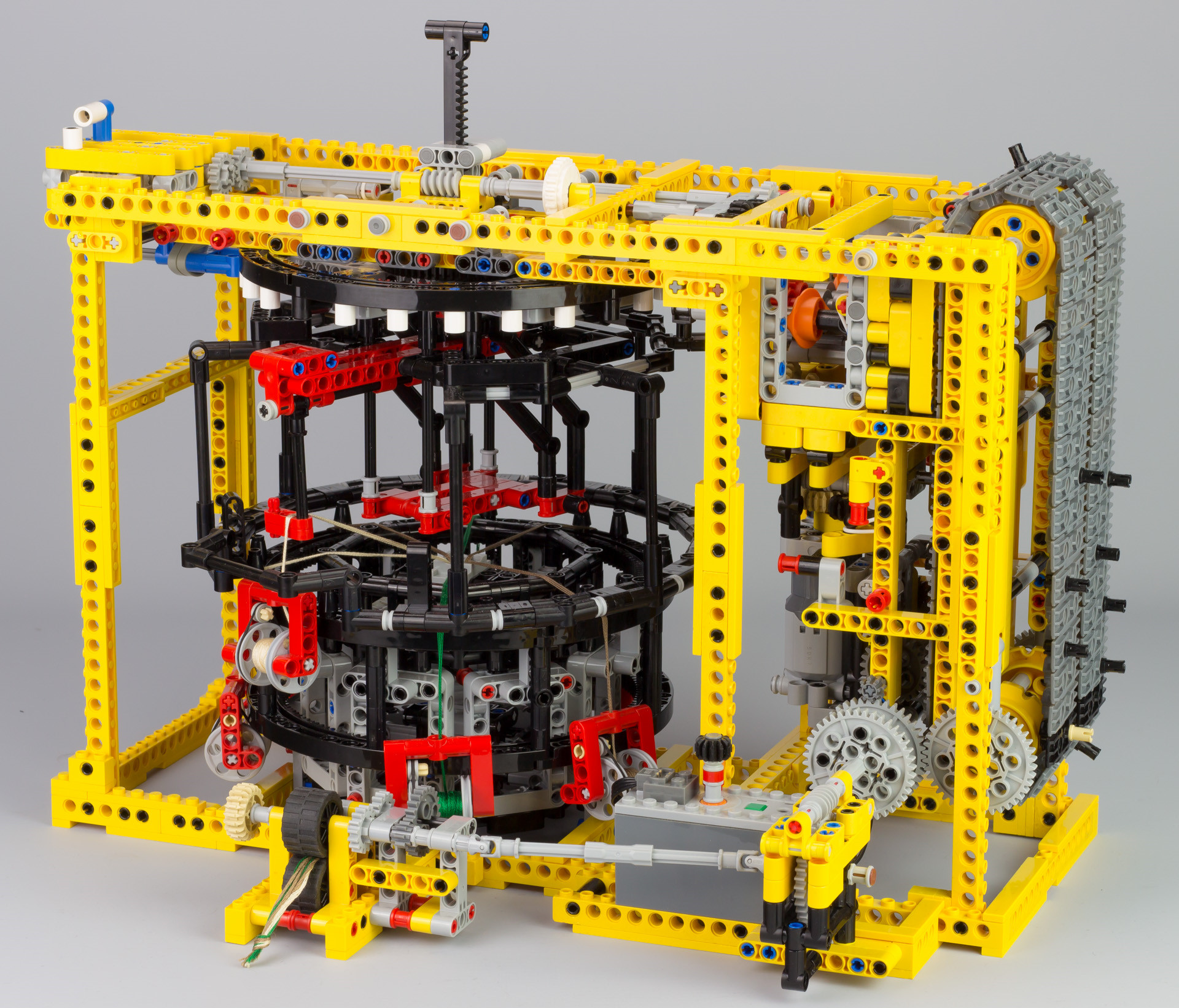

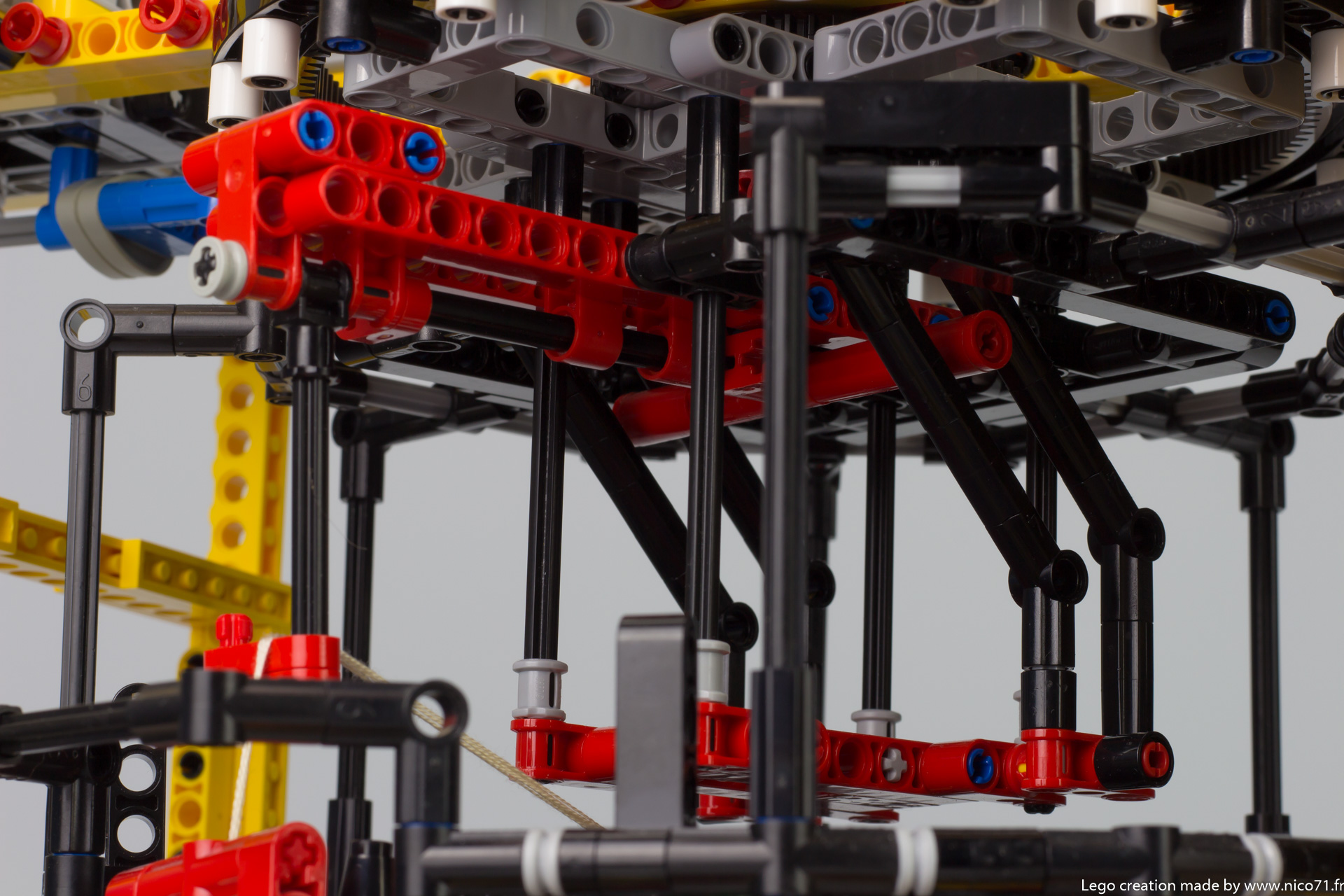

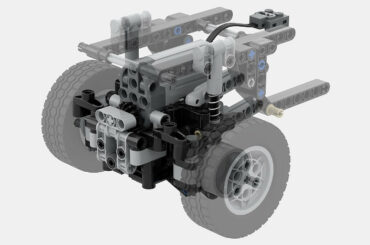

The first gearbox operates the hook, by moving a rack which is mounted on a small turntable to enable the rotation of the main ring. The hook can be lifted or lowered independently of the position of the main ring. The hook assembly is built with two diagonal ramps to allow a combination of horizontal and vertical displacements of the hook when the whole assembly is moved. It enables to catch the reel in the centre, and then lift and go away to prevent jamming with the other reels. A clutch in the drive train enables to come against the end stops and force a little to be sure to be in position (replaced on the 11/04/20 by a clutching system using a differential cage).

The second gearbox is connected to a rotating lever which makes oscillate a fork to make rotate the main ring. The whole assembly of the fork is connected to this ring, enables the positioning around the circle to catch and release the different reels. This part was the most difficult to create, because it had to be very precise in order to move the main ring on the correct position. I have tested many solutions with motor and servo motor, and/or switch and movable end-stop. But each time the result was not enough precise or reliable which make jamming the machine after some time.

The trick I used is rather simple : I have synchronised the speed of the actuator with the brain’s tracks. In order that during the displacement of 2 links of the tracks, the lever of the oscillating fork make 2 turns.

This trick was a good start but not enough to have a reliable and repeating position for the long time. In fact due to the play in the gearing and the shifting mechanism (because it is Lego), the shifting moment when the function is operated is not exactly the same each time. That, combining with the fact that the main ring always rotates in the same direction, make the main ring tends to have an increasing rotation shift. I have figure out this problem with the same trick used in many other machine with cancelling the play by going in the opposite direction each time the assembly go in one direction. That is why, you can see on the video that the main ring rotates, stops, and goes backward a little, this is for cancelling the play to have a reliable and precise functioning.

Last device is the black ring which encircles the reels, as shown in the video, this device has been designed to push down the reels when they unwind naturally because of the main winder. It enables to have a reliable functioning until the reel are empty.

Performance

Even if the machine is big and fully automated, the global speed of braiding is not very fast ! It is explained by the Kumihimo principle which is to move each reel after each other which makes a real rope but takes more time than a classic rope maker. But also because the movements of the machine are rather slow, especially rotating the ring. I have tried to increase the speed but the inertia of the main ring make it rotate too much, that is also why you can see a small friction wheel on the ring.

The Lego solutions I have chosen are also an answer to the slow speed. As I use gearboxes and tracks, I have to have some time between two movements because of the building with pins and knobs, by passing to a neutral position (I can’t go back and forth without passing through neutral). This point, combining with the back movement to cancel the play make the rotation of the ring the critical slowest movement of the machine. That is why I have reworked many time the tracks-pin-layout to make it running faster by combining the movements when it is possible (start rotating when the hook is lifted, etc.). But I will also test with the new Control+ hub and servo motor in direct drive functions when I have, in order to test the maximum speed with programmable servo motor.

The result is a real braid that the tightness can be adjusted by replacing the gear ratio in the main winder.

Pictures and Video

Building Instructions

As usual, I have made building instructions, but I had no idea how long and difficult it will be, because of the rendering of the flexible parts and the many sub assembly. Therefore I present you the biggest instructions I have ever done, with 487 pages ! This instructions reach the standard of quality of pro-instructions with detailed step by step assembly with list of parts and important note during the building (you can check the sample below). I have also made a “how to set up” video for the machine (see at the end of the article).

You can also checked it on Rebrickable and export in whatever format you want :

You can buy the instructions with the following button for 10€. You can also buy other building instructions and get an automated discount. You will get 15% off for 2 PDF, and 20% off for 3 PDF on the total), available for all the instructions for sale on nico71.fr.

See it on the shop :

Kumihimo Braiding Machine

After your payment, you will be redirected to a page for downloading your instructions, and will receive also the link to download by email. Please check the spam box and be patient to receive it. If you have trouble to download your copy of the PDF after payment or open the document, do not make a paypal dispute, please contact me using the contact form. The link to download the instructions expires within 24h. Contact me if you have lost your instructions. Note that you can print it, but not copy or distribute. Thank you for supporting my work 🙂

Set up of the machine

Regarding the black rubber band (x7), you can use every Ø15mm pony tail rubber band as long as they are less elastic than the 85543 rubber band. The rubber band has to prevent the free rotation of the reel, but do not have to lock it when you pull it slightly.

Regarding the reel’s thread (at least 7x 1m), I recommend DMC thread for the quality, but you can test with many other brands or raw materials. Avoid the too big or fluffy materials like the wool.

Please follow this video to set up the braiding machine when you have built it :